Tapered Roller Bearings

Supertembo Tapered Roller Bearings

support high radial loads and axial loads in a single direction and are available in two and four-row versions which are capable of taking axial loads in either direction. Tapers can be supplied with high strength cages (optimized designs) and in a range of advanced special materials for more arduous applications.

Product Features:

- Material Technology: Hardened high carbon chromium steel

- Advanced Materials: Are available for more arduous conditions

- STB tapered roller bearings offer higher load ratings

- STB cage optimized for large tapered roller bearings installed in planetary carriers

- Segmented plastic cage for inner diameters of more than 1000 mm

- Metric and imperial dimensions

- Outer diameters up to 2500 mm

- Product Benefits:

- High radial and axial loads in one direction

- Axial loads in both directions when arranged in pairs

- Medium speeds

- Small clearance range when bearing pairs are adjusted during mounting

- Higher permissible speeds by improved raceway surface roughness

High accuracy pressed steel cage controls roller position resulting in low heat generation and reduced wear properties.

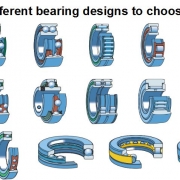

Supertembo range of Tapered Roller Bearings includes single row taper roller bearings, double row taper roller bearings, four-row taper roller bearings and more.

Please follow this link for a detailed description of our products